Factors Influencing Today’s Manufacturing Technology Trends

Feb 16, 2023

iCrowdMarketing powered by iCrowdNewswire

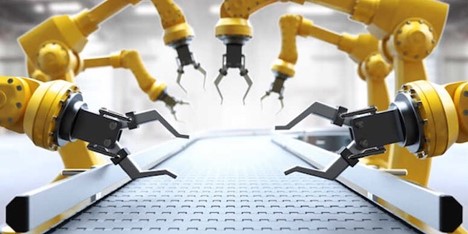

Manufacturing remains one of the main drivers of the national economy. A robust manufacturing sector is efficient and up-to-date with current trends. Machine parts manufacturers stand to benefit from these trends, which are driven by the combined or single influence of factors such as market demand and competition, emerging technology, talent, supply chain, and sustainability.Machines parts manufacturing is important due to the extensive use of machines in almost every industry. Current manufacturing trends in this area feature CNC machining capabilities, smart devices, automated machines, and the use of artificial intelligence. The aim of manufacturers is in line with market demands, which is to ensure more accuracy and fewer errors in the production process.

Here we explore the factors influencing current manufacturing technology trends. The report focuses on the five major influencing factors including the respective aspects of manufacturing technology trends involved. This is an effort to provide insights into the current state of machine parts manufacturing technology and future possibilities.

1. Emerging Technologies

The emergence of new technology has transformed the technological capabilities used by machine parts manufacturers.

One of the latest application in machining services is the computerized numerical control (CNC) machining technology. This technique is subtractive because it removes pieces from a material to create a specified machine part. It is currently the preferred machining method because it offers the benefit of high tolerance. In turn, it makes it possible to accurately produce machine parts with high precision or fit with others.

CNC machining can be used for different processes during machine manufacturing. This makes the technique effective for faster manufacturing. It can be used in vertical drilling of the surface of the material, milling (cutting as it rotates in the same direction as the material), and turning to create cylindrical machine parts.

CNC machining is also versatile in terms of the materials used to make machine parts. It can work with metals, plastic or a combination of both. Materials chosen for CNC machining should be mechanically strong, temperature resistant and machinable. Examples include aluminium, stainless steel, and brass for metals; and acrylonitrile butadiene styrene (ABS), nylon and polycarbonate for plastics. These qualities makes CNC machining an important technique in current manufacturing trends.

2. Market Demands

Machine parts manufacturers are influenced by the need to produced market responsive and high-end products. The machine parts market today demands precision, high performance and light weight products. This has driven machine parts manufacturers to seek corresponding technology that can meet these demands. CNC machining technology, for instance, enables the production of parts that require high tolerance (precision) and complex geometries.

With good CNC machining services manufacturers can precisely produce several machine parts with a tolerance as high as +/-0.04mm. This means that CNC machining can produce materials that differ from the original model within this range. During the process, the machining carves out the material dimension and features as determined by a blueprint from computer aided-design.

Secondly, market demands for customized and timely products, has influenced technology used in rapid manufacturing services of machine parts. The need for shorter product development cycles has influenced the use of manufacturing technologies that support rapid prototyping and development of products.

The latest technology trend in rapid prototyping is 3D printing computer aided design (CAD). This techniques helps to assemble models or prototypes of machines parts to mimic the desired final product. During rapid prototyping, 3D printing is used to add layers to the model, while machining technologies such as CNC are used to mould it to create a desired design.

3. Talent Resources

These refer to the human skills and abilities employed in the machine parts manufacturing industry. Current technology used in manufacturing sector has been influenced by the availability and mobility of high-end talent. The availability of machinists and engineers skilled in creativity, innovation and problem solving is important influences the choice of technology machines parts manufacturers use.

Automation in machining services is a result of need for precise, more efficient and low-cost alternatives to acquiring and training a desired talent pool. Other alternatives include the use of smart chip technologies and sensors to provide more accurate data and insights about the machining and parts manufacture process.

4. Supply Chain Needs

The need for effective coordination of activities, resources and materials involved in production has influenced the use of recent technologies in machine parts manufacturing. The aimis to ensure that resources are well integrated to attain efficient and rapid manufacturing.

The internet of things (IoT) has been used in facilitating workflow and sharing of information. It refers to the networking capabilities that allow sharing of information between machines. With IoT, machines parts manufacturers are able to coordinate communication with suppliers and their customers throughout the product development cycle. This became more important in the recent past, during the pandemic where movement of people and materials was limited.

Manufacturers and customers can share and discuss the prototypes before the actual production begins. Similarly, manufacturers can release an earlier version of the product in the marke and receive feedback for adjustments without disrupting the product development work schedule. Generally, everyone involved in the product development cycle is actively involved through IoT.

Conclusion

Overall, current trends in technology used in manufacturing are influenced by emerging technology itself, market demands, talent resource availability and supply chain needs. Emerging technology such as CNC machining and 3D printing enables rapid prototyping and shorter product development cycles. The trend is also driven by the market needs for high-end product features, supply chain needs and the need for high accurate skills. Collectively, these factors contribute to a sustainable approach to machine parts manufacturing. It is likely that they will continue influencing manufacturing technology trends in the future.

Tags: English