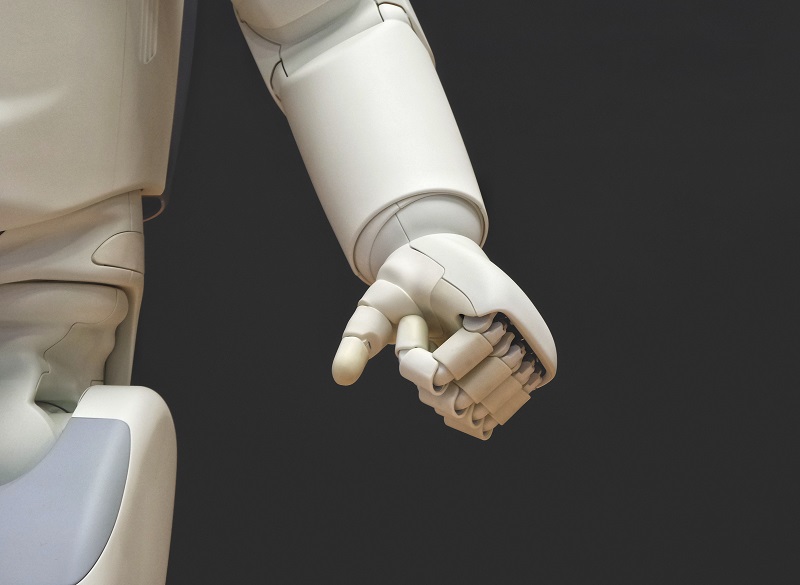

The Robotic Arm: A Technological Milestone

May 05, 2022

iCrowdMarketing powered by iCrowdNewswire

Industry automation has been the object of controversy for decades. With the concept of robotics developing centuries ago, setting up automation in commercial environments didn’t happen until the 1970s. This innovation has taken center stage in several industrial processes.

The most notable of these innovations is the robot arm. The industrial robotic arm was invented in 1962 by a self-taught engineer-George Devol. This technology creates critical concerns; is it sustainable? Does it aim to replace an aging workforce, or is it meant to supplement economic deficiencies?

Many people misunderstand the intentions of innovation in robotics. These issues need to be addressed for companies, small and large, to embrace this technology as a resource.

Key Robot Arm Facts and Statistics

The robotic arm integrates seamlessly into several industrial processes. Most of its value is in manufacturing, assembly, and intricate surgery. This technology is precise, requires minimal supervision, and improves product quality. To confirm how substantial their industry penetration is, here are some statistics you should be aware of;

- Collaborative robots account for 34% of industrial robot purchases. Experts predict that this figure will increase substantially due to Smart-technology and other innovations.

- It wasn’t until 1970 that the robotic arm’s potential emerged. This technology has found applications in military circles and other precise industry functions. Modern varieties are now available for consumer use and menial applications, such as pick and place roles.

- The adoption of robotics in 2022 is projected to rise by 100%. Industries have seen the value of this technology and are now investing in automation.

- Cost-efficiency and precision are the primary benefits of robotic arms. These perks reduce production time and maintain brand quality. Automotive assembly lines and large manufacturers use these features to facilitate top-tier brand quality.

- Robotic arms are now a common feature in caregiving. They function well in surgical practice and other healthcare circles. Some also assist the physically disabled and the elderly to gain access to hard-to-reach areas. The use of robot arms in 2022 has increased by 50%. This figure shows that this technology is critical in palliative care.

Robotic Arms Today

In terms of industry penetration, robot arm integration has increased by 60% in the last two years. This figure is for manufacturing, automotive assembly, medicine, and electronic production. It is a significant contributor to automation technology and is the fastest-growing innovation. This component also makes up 34% of the 2 million robotics purchased worldwide.

Robot arms are now a common feature in consumer and retail circles. Value analysis shows that robot arms help shelving for small retail stores, and homeowners use them for various purposes. Consumer robots perform household chores such as vacuuming and storage. With stock-taking and product placement, retail stores employ robot arms to organize stores and make items more accessible to customers.

Large companies are also beneficiaries of this technology. While previous robots were cumbersome and difficult to integrate, new ones are smaller, mobile, and more efficient. They also require less floor space. This feature makes them easier to run on factory floors. This innovation has made machine-human interactions safer and more effective.

Car assembly and large manufacturing companies now have equipment that can be fully automated and operated from a central control unit. This control hub means safer function and reduced risk of injury. There is still the limitation of robots programmable to handle entire industrial processes, but it is just a matter of time before this is achievable.

State of Robotic Integration

There are currently over 2 million robotic units worldwide. Automation technology began in Asia, the U.K, and the U.S.A. The automotive industry is at the top of industrial automation, with various manufacturing processes following closely behind.

Companies that lead in mass production have one thing in common-industry automation. This technology improves the operational capacity to maximize output. It is also a testament that robot arms can function effectively with very little infrastructural investment. The cost-saving element of this technology makes it critical if companies want to streamline production processes. The mass adoption of robotics is also a primary contributor to establishing and maintaining a competitive edge.

The Concept of Machine Learning and Smart Manufacturing

George Devol and Joseph Engelberger envisioned an age where robots could function autonomously and maintain efficiency. Modern robot arms are inching towards this goal by using integrated software to create Artificial intelligence.

Modern robots are now achieving tremendous levels of virtual perception, allowing them to function autonomously. Smart manufacturing is now a reality, and with the help of IoT technology, manufacturers can coordinate several processes.

Smart-Technology reduces the need for constant reconfiguration of robots, allowing companies to reassign robots effectively.

The Internet of Things has also led to a digital transformation leading the line in robotic circles. There is a significant improvement in human/machine interactions and machine/machine inter-connectedness. Modern robots complement functions and coordinate to improve production processes.

This feature allows large companies to merge functions in multiple factories and create a central operation point. Although this is not yet a reality, it is a significant step towards allowing companies to control entire infrastructures.

Think of a scenario where a large manufacturer can consolidate operations in every branch. This merging will allow them to run operations without having physical access.

Is Robotics Technology Sustainable?

Sustainability indicates the ability of robotics technology to meet current and future human needs. Do robotic arms have this potential? Based on the statistics above, it is clear that robotics facilitate effective resource exploitation. This technology improves output and also protects humans from tedious, harmful tasks.

A robotic arm can work in tight spaces, handle heavy and toxic components and improve production. Automation presents an opportunity to run factory functions with minimal risk. The question of sustainability stems from increased employment opportunities since the 1990s.

Some of the elements of sustainability are evident in the fundamental advantages of robotic arm integration. Features such as improved operational flexibility, high ROI, and workplace versatility show that this technology adds value.

Bottom Line

The robot arm is an innovation milestone. It creates a system where humans and machines can effectively work together to improve production. There are concerns about sustainability, but experts address this with facts. Robots do not replace the human labor force-they create an environment where both parties can consolidate their efforts for better results.

Tags: English